When a generic drug company submits an application to the FDA, they’re not just asking for permission to sell a cheaper version of a brand-name drug. They’re asking to prove their product is identical in every way that matters-safety, effectiveness, and how it works inside the body. But more than half the time, the FDA says: "Not quite." That’s when a deficiency letter arrives. It’s not a rejection. It’s a detailed checklist of what’s missing, wrong, or unclear. And for many small companies, it’s the biggest roadblock to getting their drug to market.

What Exactly Is a Deficiency Letter?

A deficiency letter from the FDA is a formal notice that an Abbreviated New Drug Application (ANDA) can’t be approved as submitted. It lists specific problems that must be fixed before the agency can move forward. These aren’t vague suggestions. They’re precise technical gaps, often backed by data from the FDA’s own lab reviews. The letter tells you exactly which section of your application failed-whether it’s the chemistry of the active ingredient, how the drug dissolves in the body, or whether your manufacturing process can consistently produce the same product batch after batch. The FDA doesn’t send these letters lightly. They’re the result of a full review by multiple teams: analytical chemists, pharmacologists, manufacturing inspectors, and bioequivalence experts. In 2023, over 70% of major deficiencies in ANDAs were quality-related. That means the problem wasn’t about marketing or pricing-it was about science and control.The Top 5 Deficiency Categories (And Why They Keep Happening)

Not all deficiencies are created equal. Some are one-time mistakes. Others are systemic failures. Based on FDA data from 2021 to 2024, these five issues appear in nearly every deficiency letter:- Dissolution Method Issues - 23.3% of all applications fail here. The FDA requires dissolution tests to mimic how the drug breaks down in the human gut. Many companies use outdated equipment or test at only one pH level. The FDA expects testing across multiple conditions (pH 1.2, 4.5, and 6.8) using the right apparatus (usually Apparatus 2 for immediate-release tablets). If your method can’t tell the difference between your drug and the brand-name version, you won’t get approved.

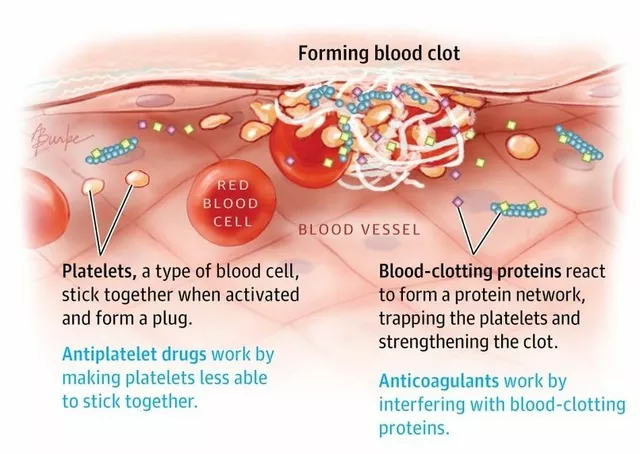

- Drug Substance Sameness - 19% of applications stumble here. The active ingredient must be chemically and physically identical to the reference drug. For simple molecules, this is straightforward. But for peptides or complex APIs, you need advanced tools like circular dichroism and size-exclusion chromatography to prove the protein folds the same way and doesn’t clump differently. Many applicants skip these tests because they’re expensive or don’t understand they’re required.

- Unqualified Impurities - 20% of letters cite this. Even tiny amounts of impurities can be dangerous. The FDA expects all impurities above 0.1% to be identified, tested for toxicity, and controlled. Many companies rely on old ICH guidelines or assume their supplier’s certificate is enough. The FDA wants full toxicology studies for any new or unexpected impurity-especially if it’s a mutagenic compound covered under M7 guidelines. Missing (Q)SAR data here can add 14 to 18 months to your timeline.

- Control Strategies for Elemental Impurities - 13% of applications are deficient here. The FDA now requires strict limits on heavy metals like lead, cadmium, and arsenic. Companies often submit generic statements like "we follow ICH Q3D" without showing how their specific process controls these elements. The FDA wants data: where the metals come from, how you test for them, and how you ensure each batch stays under limit.

- Manufacturing Process Gaps - This is the most common category overall. The FDA checks if your lab-scale process matches what you’ll use in commercial production. If your bioequivalence batches were made on a small mixer but your factory uses a different blender, you’ll get a deficiency. The agency wants proof that your process is robust, scalable, and controlled-not just "it worked once in the lab."

Why Complex Drugs Are Getting Rejected More Often

It’s not just about quantity-it’s about complexity. Modified-release tablets, topical creams, and peptide-based drugs are growing fast. But they’re also failing more often. In 2023, these complex generics made up only 22% of all ANDA submissions-but 38% of all deficiency letters. Why? Because they’re harder to copy. A tablet that releases medicine over 12 hours isn’t just a pill with a coating. It’s a system of polymers, particle sizes, and manufacturing steps that must be perfectly matched. The FDA looks for proof that your version behaves the same under real-world conditions-like stomach movement, food effects, and pH changes. Most applicants don’t test for this. They assume if the dissolution profile looks similar on paper, it’s good enough. It’s not. Peptide drugs are even trickier. A small change in how the molecule folds can make it ineffective-or even harmful. The FDA now requires at least three advanced analytical methods to prove structural similarity. Many companies don’t have access to the equipment or expertise. They submit incomplete data and wonder why they got a deficiency.

Who’s Getting Deficiency Letters-and Why

It’s not just new companies. But new companies are hit hardest. Firms with fewer than 10 approved ANDAs have deficiency rates 22% higher than those with 50 or more. Why? Experience matters. Established companies know what the FDA expects. They’ve seen deficiency letters before. They’ve had pre-submission meetings. They know which tests are non-negotiable. Small companies often make the same mistakes:- They skip pre-ANDA meetings because they think it’s a waste of time or money.

- They rely on their CMO (contract manufacturing organization) to handle regulatory stuff without understanding the technical requirements.

- They use academic-style development-focused on proving a concept-instead of commercial-scale validation.

How to Avoid a Deficiency Letter

You can’t eliminate risk entirely. But you can dramatically reduce it. Here’s what works:- Request a pre-ANDA meeting. Companies that do this see deficiency rates 32% lower. Use this meeting to ask: "What are the top three things you’ll reject me for?" The FDA will tell you. Take notes. Follow up in writing.

- Invest in dissolution method development. Don’t copy the brand’s method. Build your own using biorelevant media and test it against multiple lots of the reference drug. Show discrimination. Show robustness.

- Do full impurity profiling early. Run forced degradation studies. Identify every impurity above 0.1%. Submit (Q)SAR data for mutagenicity. Don’t wait until the FDA asks.

- Document everything. Applications with detailed development reports have 27% fewer deficiencies. The FDA doesn’t just want data-they want context. Why did you choose this method? Why did you reject that excipient? What did you learn from your failed batches?

- Use Quality by Design (QbD) principles. This isn’t jargon. It’s a practical framework: define your target product profile, identify critical quality attributes, and design your process to control them. The FDA loves QbD. It reduces surprises.

The Real Cost of a Deficiency Letter

A deficiency letter isn’t just a delay. It’s a financial hit. Each additional review cycle costs an average of $1.2 million in extra testing, staffing, and delays. For a small company, that could mean going bankrupt before approval. The economic pressure is real. High-revenue generics (those expected to make over $100 million a year) have 18% fewer deficiencies. Why? Because they can afford to get it right the first time. They hire experienced regulators. They run multiple pilot batches. They validate every step. The FDA’s Competitive Generic Therapy (CGT) program shows what’s possible. Products in this program-designed for drugs with little competition-have a 73% first-cycle approval rate, compared to the industry average of 52%. Why? Because the FDA gives them extra guidance, faster reviews, and clearer expectations.What’s Changing in 2025 and Beyond

The FDA is trying to fix this system. In 2023, they launched the "First Cycle Generic Drug Approval Initiative," which includes new templates for common deficiency responses. In April 2025, they released specific examples of how to fix dissolution and impurity issues-something they never did before. They’ve also created specialized review teams for complex products. And by Q3 2026, they plan to roll out AI tools that scan submissions before they’re even sent in. These tools can flag missing data, mismatched methods, or incomplete reports-before the FDA sees them. Early tests show this could cut preventable errors by 35%. Industry analysts predict that by 2027, first-cycle approval rates could jump from 52% to 68%. That means more generic drugs reaching patients faster. But only if companies stop treating the FDA like a hurdle-and start treating it like a partner.Final Thought: It’s Not About Cheaper. It’s About the Same.

Generic drugs save the U.S. healthcare system over $300 billion a year. But that only works if they’re safe and effective. The FDA isn’t trying to block you. They’re trying to make sure your drug does exactly what the brand-name version does-no more, no less. If you’re submitting an ANDA, don’t just check boxes. Understand the science. Anticipate the questions. Build your application like your life depends on it-because for many patients, it does.What happens after I get a deficiency letter from the FDA?

You have 180 days to respond with a complete, point-by-point reply addressing every deficiency. Your response must include new data, revised protocols, or updated documentation. The FDA will then re-review your application. If they’re satisfied, they’ll approve it. If not, you may get another deficiency letter-or a complete rejection. Most companies fix the issues on the second try, but each delay adds $1.2 million in costs.

Can I appeal a deficiency letter?

No, you can’t formally appeal a deficiency letter. But you can request a meeting with the FDA to discuss their findings. Many companies use this to clarify misunderstandings or provide additional context. If you believe the FDA made an error, your best path is to submit a thorough, data-backed response and request a re-review. The FDA is open to being convinced-by evidence, not argument.

How long does it take to get an ANDA approved after submitting a deficiency response?

After you submit your response, the FDA has 60 days to review it. If they need more information, they may issue another deficiency letter. If they’re satisfied, they’ll approve the application. On average, a second-cycle approval takes 5 to 8 months from the date of your response. First-cycle approvals take about 10 months total.

Are deficiency letters public information?

No, deficiency letters themselves are confidential and protected under FDA regulations. However, the final approval decision and a redacted version of the application (with proprietary information removed) are posted on the FDA’s Drugs@FDA website. Some companies voluntarily release summaries of their deficiencies as part of investor disclosures.

What’s the difference between a deficiency letter and a complete response letter?

There’s no difference in practice. The FDA uses "deficiency letter" for generic drug applications (ANDAs) and "complete response letter" for brand-name drugs (NDAs). Both mean the application isn’t approvable as submitted. The terminology is just a historical artifact of different review divisions. The process, impact, and next steps are identical.

This is why my last ANDA got shredded. Dissolution method? Used Apparatus 1 by accident. FDA came back like 'lol no.'

Another generic company thinking they can bypass QbD with a PowerPoint and a prayer. The FDA isn't your undergrad lab TA. You're not submitting a thesis-you're submitting a life-or-death product. Stop treating regulatory science like a suggestion box.

i just wanna say thank you for writing this. i work at a small pharma co and we got a deficiency letter last month on elemental impurities. didn't even know we needed to track arsenic from our raw materials. this helped me sleep at night.

There's an interesting metaphysical layer here: the FDA isn't rejecting drugs. They're rejecting the illusion of sameness. We think identical means chemically equivalent. But true equivalence is systemic-process, context, consistency. The molecule doesn't care what we call it. The body does.

Let’s be real. Most of these deficiency letters are just FDA’s way of protecting Big Pharma’s margins. You think they care about peptide folding? No. They care that your $2 pill might steal $2000 from their quarterly report. The science is a smokescreen.

The United States deserves safe, effective, and properly regulated generic medications. Anything less is a betrayal of public trust. This article is accurate, thorough, and reflects the rigor our healthcare system demands.

I just got my first deficiency letter 😭😭😭 but now I know what to fix!! Thank you for this!! 🙏💖 I'm going to re-do the dissolution profile with biorelevant media and I swear I'm gonna make it 🤞🧪

The cost of deficiency letters is unacceptable. $1.2 million per cycle. That’s a small hospital’s annual budget. We need systemic reform not just better compliance. Patients are paying for this inefficiency.

This is gold. I’ve been in this game 15 years and still learn something new every time. Especially the bit about QbD. Seriously, if you’re not using QbD, you’re just gambling with patient safety. 🤝❤️

You people are pathetic. You spend 18 months trying to copy a pill and then act like the FDA is the enemy. If you can’t even replicate a drug properly, maybe you shouldn’t be in pharma. Go sell kombucha.

The dissolution method issue? That’s the silent killer of generics. It’s not about the tech-it’s about the mindset. You don’t test dissolution to pass an audit. You test it to ensure the patient gets the same kick in the gut as the brand. That’s the soul of this work.

To all the small teams out there: don’t panic. Every big player started where you are. I once sent an ANDA with the wrong excipient code. Got a deficiency letter that was 12 pages long. Took me 8 months. But I learned. Now I train new hires. You got this. One batch at a time.

I’ve reviewed over 200 ANDAs in my career and let me tell you-most deficiency letters are avoidable. But here’s the real problem: companies outsource everything to CMOs and then act shocked when the CMO doesn’t know what a QbD is. You can’t outsource regulatory responsibility. It’s like hiring a chef to cook your wedding cake and then blaming them when the icing melts because you didn’t tell them the venue was in the desert. The FDA isn’t being unreasonable. You’re just lazy. And now you’re wasting taxpayer money and delaying life-saving meds. Fix your process. Or get out.